Have you ever wondered what bowling balls are made of?

The choice of a bowling ball will determine how you’ll best experience the sport.

In this blog post, we'll take a closer look at the different materials used to make bowling balls and discuss the pros and cons of each one.

We'll also help you decide which material is right for you.

So if you're curious about the construction of your favorite bowling ball, read on!

Contents

- 1 What Are Bowling Balls Made Of?

- 2 Different Types of Bowling Balls

- 3 What Materials Are Bowling Balls Made Of? (Raw Materials)

- 4 How Are Bowling Balls Made? (The Manufacturing Process)

- 5 What Does a Bowling Ball Coverstock Do?

- 6 Types of Bowling Ball Coverstocks

- 7 What Is Inside of a Bowling Ball - Types of Bowling Ball Cores/ Weight Block

- 8 Specifications of a Bowling Ball

What Are Bowling Balls Made Of?

Bowling balls have four (4) different coverstock materials: plastics, urethanes, three different reactive resins and proactive (particle) resins. In addition, some manufacturers also add cores made from materials like ceramic or particle board to their bowling balls in order to provide better stability and performance.

Different Types of Bowling Balls

There are many different types of bowling balls available on the market today, each designed for a specific purpose.

The most common types of bowling balls are:

- Tenpin ball: The commonly used bowling balls with three holes used for a ten-pin bowling game.

- Duckpin bowling ball: It is smaller than the ten-pin ball just around 4.75–5.00 inches in diameter. It doesn’t have any holes. Pins to be knocked down in a duckpin game are usually 60% smaller than the regular pins.

- Candlepin bowling ball: This is the smallest ball of all, weighing around 2 lbs. It has no holes.

What Materials Are Bowling Balls Made Of? (Raw Materials)

Most bowling balls are made of a type of hard plastic called polyester. The outer surface of the ball is smooth, and the inside is filled with a series of small, hard pellets. This design helps to give the ball the desired level of bounce and spin.

Polyester is a durable synthetic fiber that is resistant to abrasion and wear. Plastic is the least common type of material used in bowling balls, but it is still an option for some manufacturers. It is a light-weight and inexpensive material that offers good durability.

Some high-end bowling balls may also contain reactive resin, which further enhances their performance.

In addition to polyester (plastic) and reactive resin, bowling balls can also be made of urethane. Urethane is a synthetic polymer that is known for its flexibility and resilience.

No matter what type of material a bowling ball is made of, it must meet certain performance standards set by the US Bowling Congress. These standards ensure that all balls are uniform in size and weight, and have the same level of bounce and rebound.

How Are Bowling Balls Made? (The Manufacturing Process)

A bowling ball is made of three layers: the coverstock, the core, and the inner core.

The coverstock is the outermost layer and is made of either plastic or urethane.

The core is the innermost layer and is made of either a solid or liquid substance. The coverstock and inner core are all vulcanized together under high pressure and heat.

Afterward, the coverstock is then sanded and polished to create a smooth surface.

The manufacturing process can be divided into 4 segments as below.

1. Making the Core

Before anything is done, a mold is made following the core shape designed during the computerized ball design process.

Here, the materials to be used are poured into core mold then allowed some time to harden.

Then ceramic cores are fired in a kiln. The manufactures can then insert the core above in a second mold then create a compound core using a material of a different density.

2. Forming the Shell

A shell is then formed by placing the finished core in a spherical mold called the coverstock.

The core is then attached to a pin projecting inward from the shell of the mold. The purpose of the pin is to hold the core in position.

Next, the core is encased by pouring the coverstock material into the mold then allowed to harden.

3. Filling the Gaps

Taking out the ball from the coverstock will reveal a hole where the core-holding pin had been. To fill the hole, a plastic dowel is cemented into the hole.

4. Finishing

Here, the bowling ball is then finished to the proper size specification. A centerless grinder is used to shave off excess coverstock.

Finally, the ball is finished to the desired texture, sanded, and polish applied.

What Does a Bowling Ball Coverstock Do?

A bowling ball's coverstock is the outer layer that comes into contact with the lane. It is made of a variety of materials, including urethane, plastic, and resin. It is also the layer that undergoes the most wear and tear, so it must be tough enough to withstand repeated impact.

The coverstock is responsible for providing traction on the lane, as well as creating friction in order to generate spin. The type of coverstock you choose will affect the ball's hook potential and overall performance.

Plastic coverstocks are the least reactive and provide the least hook potential. They are best suited for dry lane conditions and picking up spares when the ball needs to thrown straight.

Urethane coverstocks are more reactive than plastic and provide moderate hook potential. They are best suited for dry/medium lane conditions.

Reactive resin coverstocks are the most reactive and provide the most hook potential. They are best suited for oily/slippery lane conditions.

When choosing a bowling ball, it is important to select a coverstock that is appropriate for the lane conditions you will be bowling on and your style of bowling.

Types of Bowling Ball Coverstocks

There are 4 types of bowling ball coverstocks as below:

- Plastic

- Urethane

- Resin or Reactive balls

- Proactive or Particle

Plastic Bowling Balls

Plastic bowling balls is the house ball, which is generally made of plastic and is intended for use on short, mat-like lanes.

While most people think of bowling balls as being made of heavy, hard plastic, the fact is that there are many balls made of a soft type of plastic.

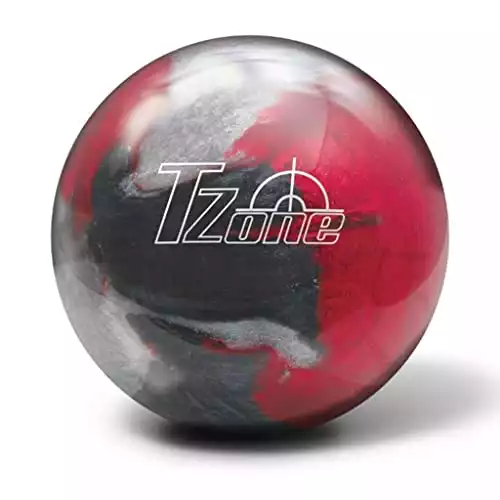

A great option to consider is the TZone Deep Space bowling ball by Brunswick. A plastic ball that is great for straight line bowling. The Brunswick TZone Deep Space is not to be overlooked. It's also a great entry-level bowling ball for beginners trying to get a handle on different lane conditions.

They typically are much softer than a urethane balls, and it will also be much more likely to bounce when it hits the pins. The house ball hook is zero.

Urethane Bowling Balls

Urethane balls are made from a type of synthetic plastic that is known for its durability and resilience. This makes them ideal for use on hard lanes, as they are less likely to crack or chip than other types of balls.

Urethane balls also tend to be far less responsive to temperature changes than other types of balls, meaning they can be used in a wider range of conditions. As a result, urethane bowling balls are an excellent choice for serious bowlers who want consistent performance. They provide a good balance between hook and control.

Reactive (Resin) Bowling Ball

Another common type of ball is the Reactive resin ball, which is designed to provide optimum hook potential and pin action. They are made of a hard plastic material that is infused with a resin compound.

This combination gives the ball a strong hooking potential while still providing a consistent roll. They are heavy balls, which are typically used by expert bowlers who need extra weight to increase their strike potential.

Reactive Pearl

Reactive Solid

Reactive Hybrid

Proactive (Particle)

Proactive (particle) coverstocks have additonal microscopic material in the coverstock that comes in contact with the lane, and creates its own friction. The surface is textured.

What Is Inside of a Bowling Ball - Types of Bowling Ball Cores/ Weight Block

The core of a bowling ball is the heaviest and densest part of the ball. It is also the largest-diameter piece of the ball, measuring between 2.75 and 3 inches depending on the size of the ball.

The core is responsible for approximately 60 percent of the weight of the ball, with the rest coming from the coverstock. The type of core used in a bowling ball can have a significant effect on its performance.

The most common types of bowling ball cores are:

Asymmetrical cores

Asymmetric or solid cores are the heaviest and densest type of core, which results in slower speeds but more power.

Pancake cores:

Pancake cores are lighter and thinner than solid cores, which leads to faster speeds but less power.

Symmetrical cores

Symmetric cores are balanced in terms of weight and thickness, which provides a good mix of speed and power. The type of core you choose should be based on your own personal style of play.

Specifications of a Bowling Ball

The following specifications must be noted while buying or producing a bowling ball as needed by the United States Bowling Congress (USBC).

- The bowling ball must be made of solid material and have a smooth surface. It should not consist of any liquid or void in the middle.

- The coverstock material must be evenly spread on the whole core.

- A bowling ball may not weigh more than 16 pounds (7.26 kg) and have a circumference of no more than 27 inches (68.58 cm).

- The surface of the ball must not be altered by any chemicals.

Frequently Asked Questions

Are Bowling Balls Made of Metal?

No, bowling balls are not made of metal. They are typically made of a type of plastic or resin. This is because metal balls would be too heavy and difficult to control when bowling.

What Coverstock Hooks the Most?

There is no definitive answer to this question since the amount of hook a coverstock provides depends on a number of factors, including the weight of the ball, the lane conditions, and your own bowling style. The Proactive (particle) coverstock is designed to aggressively hook more than the urethane, reactive resins and plastic coverstocks.

What Were Bowling Balls Made of in the Past?

The composition of bowling balls has changed over time. Early balls were made of wood, but by the early twentieth century, they were primarily made of vulcanized rubber. In the mid-twentieth century, rubber bowling balls were phased out and polyurethane bowling balls were introduced and are now the material of choice for most serious bowlers.

The very first bowling balls were made out of wood. Lignite was a common type of wood used during the 1500s. Other woods that have been used in the production of bowling balls include maple, beech, boxwood, andlder. Over time, different ways of laminating wood

What Wood Is Bowling Balls Made Of?

There are actually a few different types of wood that bowling balls can be made from. The most common type of wood used for bowling balls is Lignum vitae, as it is strong and durable. Other types of wood that have been used in the past include maple, oak and birch.

Related Articles

Bowling balls are made of a variety of materials, the most popular being polyester or plastic, urethane and resins. Each material has its own benefits and drawbacks that affect how the ball performs.

Some bowling balls are even designed to mimic the characteristics of other materials, giving bowlers more options to choose from.

No matter what type of ball you use, it’s important to understand how each one behaves so you can make the best choices for your game.

Kira Byrd, a Certified Fraud Examiner, holds a B.S. in Accounting from the University of Alabama at Birmingham. With a passion for bowling from her childhood, Kira has poured her expertise and personal experiences into creating and nurturing Bowling For Beginners. Kira's mission is to meet new bowlers where they are and guide them toward consistently achieving higher scores. With a focus on skill development and strategic techniques, she empowers readers to take control of their game and unlock their true potential.

Bowling For Beginners embodies strict editorial integrity, ensuring reliable and unbiased information. Kira's commitment to delivering valuable insights and practical strategies is reflected in every article. Here's an explanation of our editorial policy and how we get money.